Stainless steel is the workhorse of virtually every professional food service environment. From prep tables and sinks to ovens and refrigerators, its sleek, non-porous surface is essential for meeting rigorous food safety standards.

However, stainless steel is not impervious to the constant assault of grease, steam, food debris, and harsh chemical cleaners found in a commercial setting. Without proper care, it quickly loses its luster, becomes unsanitary, and can even start to rust.

Mastering the correct, professional techniques for cleaning stainless steel in a commercial kitchen is vital. It’s the difference between a compliant, efficient kitchen and one facing health code violations and premature equipment failure.

This comprehensive guide breaks down the methods, approved chemicals, and essential routines used by experts to not only clean but also preserve your costly stainless steel investment.

Why Stainless Steel Cleaning is Non-Negotiable in Commercial Kitchens

Stainless steel is chosen for its durability and inherent Cleaning Guide for Home & Kitchen resistance to corrosion. However, its longevity depends entirely on your maintenance routine.

The Health and Safety Imperative

In a commercial kitchen, cleanliness is paramount. Stainless steel surfaces that are routinely cleaned and sanitized prevent the buildup of pathogens, cross-contamination, and bacteria.

-

Grease and grime are breeding grounds for bacteria, which can lead to foodborne illnesses.

-

The surface must be cleaned down to the grit finish to remove all organic matter before it can be effectively disinfected.

-

Following a strict cleaning schedule ensures compliance with local health department regulations.

Protecting Your Kitchen Investment

Commercial stainless steel equipment is expensive. Incorrect cleaning methods—such as using abrasive pads or corrosive chemicals—damage the Clean Kitchen Cabinets material’s chromium oxide layer, which is what provides its corrosion resistance.

-

Scratches and pitting allow moisture to penetrate, leading to rust.

-

Proper cleaning and buffing maintain the equipment’s aesthetic appeal and resale value.

-

By preserving the protective layer, you significantly extend the lifespan of your tables, sinks, and appliances.

Essential Pre-Cleaning Steps: The ‘Must-Do’ Foundation

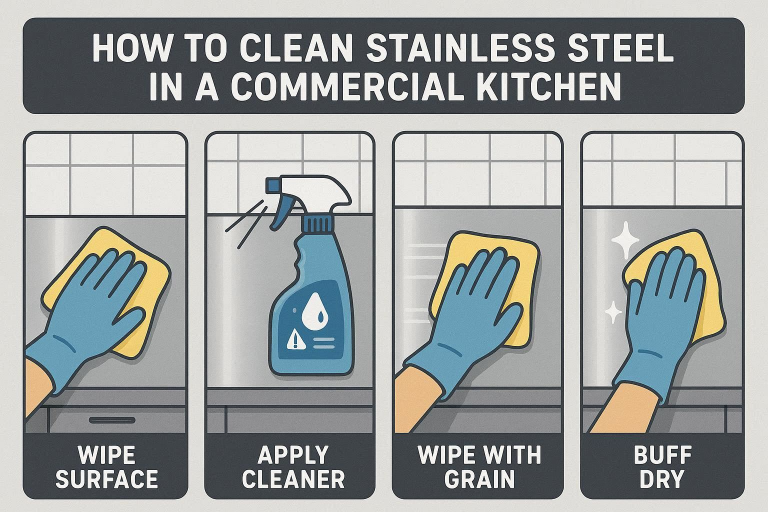

Before you introduce any cleaning solution, two fundamental steps must be completed. Skipping these steps is a primary cause of streaks, scratches, and lackluster results.

Clearing the Debris and Grime

First, remove all visible food particles, spills, and deposits. Use a soft sponge or a damp microfiber cloth to wipe down the surface.

Tip: For heavy, dried-on grease or carbon build-up, use a plastic scraper or a nylon brush before wetting the entire surface. This prevents simply spreading the stubborn grime around.

Identifying the Stainless Steel Grain

Stainless steel has a visible “grain”—tiny, microscopic lines that run either horizontally or vertically along the surface. You must always clean with the grain.

-

To find the grain: Look closely at the steel. The faint lines will resemble the grain of wood.

-

Why it matters: Wiping against the grain can drive dirt and cleaner particles into the tiny grooves, causing streaks and potentially scratching the surface, making it susceptible to corrosion.

Commercial-Grade Stainless Steel Cleaning Methods

The cleaning solution you use depends on the severity of the mess, ranging from light daily soil to baked-on grease.

Daily Routine: Mild Soap and Water

For routine, end-of-shift cleaning, a simple, non-abrasive solution is all you need.

-

Mix mild dish soap or an alkaline detergent with warm water in a clean bucket.

-

Dip a microfiber cloth or non-abrasive sponge into the solution.

-

Wipe the entire stainless steel surface in the direction of the grain.

This method is highly effective for removing surface grime and fingerprints without damaging the finish.

Addressing Tough Stains and Built-Up Grease (Deep Clean)

When daily wiping isn’t enough, you need to turn to stronger, but still safe, methods for deep cleaning.

The Power of Baking Soda Paste

For stubborn spots, burnt-on food, or minor discoloration, baking soda is an excellent, non-toxic, mild abrasive solution.

-

Mix baking soda with a small amount of water to create a thick paste.

-

Apply the paste to the stained area.

-

Let it sit for a few minutes to break down the grime.

-

Gently scrub with a soft cloth or sponge, again following the grit finish.

Using Specialized Commercial Cleaners

Many commercial kitchens opt for dedicated stainless steel cleaner products. These are specifically formulated to clean and often polish the surface without damaging the chromium oxide layer.

-

Look for cleaners that are alkaline-based and explicitly chloride-free.

-

Spray the cleaner in an “S” motion across the surface and wipe clean with a dry, lint-free cloth.

-

Always follow the manufacturer’s directions for contact time and rinsing.

Sanitizing and Disinfecting Stainless Steel Surfaces

Cleaning removes debris; sanitizing kills germs. This is a critical distinction in a commercial environment.

-

Clean First: You must first clean the surface using one of the methods above.

-

Apply Sanitizer: Use a food-safe commercial sanitizer solution (often a mild bleach/water mix or a quaternary ammonium compound) according to its dilution instructions.

-

Ensure Contact Time: Allow the sanitizer to remain on the surface for the specified contact time (often 30 seconds to a few minutes) to ensure germ kill.

-

Air Dry or Wipe: Some sanitizers require a rinse, while others can be left to air dry. Always follow the product label and local health codes.

The Critical Step: Rinsing and Drying

Many stainless steel problems—streaks, spots, and potential corrosion—stem from improper rinsing and drying.

Rinsing to Prevent Chemical Residue

After using any soap, detergent, or specialized cleaner, you must thoroughly rinse the surface with clean, warm water.

-

Residue from cleaners can leave a sticky film that attracts dirt.

-

More importantly, detergent residue left on the surface can etch the steel over time, leading to premature damage and pitting.

The Golden Rule: Drying Immediately

Leaving water on stainless steel is the fastest way to invite water spots, streaks, and even rust, especially in high-humidity areas.

-

Use a clean, dry microfiber cloth or squeegee to wipe the surface dry immediately after rinsing.

-

The goal is a completely dry surface with no visible moisture, ensuring a streak-free shine.

Polishing and Protection: Restoring the Luster

Once the surface is clean and dry, the final step is to polish it for a lasting shine and added protection.

Using Commercial Stainless Steel Polish

Specialized stainless steel polishes often contain oils that fill the microscopic grain, masking small scratches and resisting fingerprints.

-

Apply a small amount of the polish to a clean, dry cloth.

-

Rub the polish into the steel, working with the grain.

-

Use a second, clean microfiber cloth for buffing the surface to a high-gloss finish.

Natural Alternatives: The Role of Food-Grade Oil

A popular, cost-effective alternative for polishing is using a light coating of oil, especially on non-food contact surfaces like appliance fronts.

-

Food-grade mineral oil or olive oil can be used sparingly.

-

Place just a few drops on a cloth and rub with the grain to leave a protective barrier against fingerprints and smudges.

-

Caution: Avoid this on food prep areas, as it can leave a greasy residue that is not ideal for food contact.

What NOT to Use: Common Stainless Steel Cleaning Mistakes

Using the wrong cleaner or tool can permanently damage your stainless steel, leading to costly replacements. Train your staff to strictly avoid the following:

Avoiding Abrasive Tools and Materials

Abrasive materials physically scratch the surface, compromising the protective layer.

-

Steel wool pads

-

Wire brushes

-

Rough scouring pads

-

Paper towels (can be too rough and leave lint behind)

The Danger of Chloride, Acid, and Ammonia-Based Cleaners

These chemicals react negatively with the steel’s protective layer.

| Chemical Type | Why to Avoid | Resulting Damage |

| Chlorides (Bleach) | Breaks down the protective chromium oxide layer. | Pitting, rust, and localized corrosion. |

| Vinegar (Acetic Acid) | Can etch and discolor the finish with prolonged exposure. | Discoloration, dulling, or etching of the surface. |

| Ammonia/Citrus | Can be too harsh and dull the finish. | Streaking and chemical residue that attracts dust. |

Always verify that your cleaning products are approved for stainless steel use.

Advanced Troubleshooting for Stainless Steel Issues

Even with the best routine, problems can occasionally occur. Knowing how to fix them correctly is crucial.

Removing Rust and Pitting

Rust is usually caused by exposure to chlorides or small carbon steel particles (from steel wool) lodging in the surface.

-

Stop the Source: Immediately eliminate any steel wool or chlorine-based cleaners.

-

Gentle Scrub: Use the baking soda paste or a non-chloride, specialized rust remover. Gently rub with the grain using a soft cloth or a nylon scrub pad.

-

Rinse & Polish: Rinse thoroughly and apply food-grade mineral oil or polish to reseal and protect the area.

Dealing with Stubborn Water Spots and Streaks

This is almost always a result of poor drying.

-

The Rubbing Alcohol Method: For dried-on water spots, dampen a cloth with rubbing alcohol and wipe with the grain. It evaporates quickly, helping to lift the spot without leaving a streak.

-

Re-Dry: The best long-term fix is ensuring a fast and complete dry with a fresh, dry microfiber cloth after every wash.

Eradicating Fingerprints and Smudges

Fingerprints are essentially oily smudges.

-

A quick wipe with mild soap and water is often sufficient.

-

For a faster fix, use a light spritz of an ammonia-free glass cleaner on a cloth, or apply a very thin coat of stainless steel polish or food-grade mineral oil to repel future marks.

Establishing a Regular Stainless Steel Maintenance Schedule

A routine is the backbone of a safe and shiny commercial kitchen. Displaying these procedures clearly helps maintain high standards and ensures staff compliance.

Daily, Weekly, and Monthly Checklists

| Frequency | Area/Task | Action |

| Daily (End of Shift) | Prep tables, sinks, appliance exteriors. | Wash with mild detergent, rinse, and dry immediately with a microfiber cloth. |

| Weekly | Hood filters, inside of deep sinks, backsplashes. | Deep clean with specialized cleaner, sanitize, and polish. |

| Monthly | Behind equipment, entire wall panels. | Inspect for signs of pitting or corrosion, apply protective coatings if needed. |

8.2 Staff Training and Procedure Display

Ensure every employee who handles cleaning knows:

-

The location of the stainless steel grain.

-

Which cleaners are chloride-free and approved for use.

-

The correct dilution and contact time for the sanitizer.

This training contributes significantly to a consistently sanitary environment.

FAQs

What is the best household item to clean stainless steel?

The best household items for routine cleaning are a mixture of mild dish soap and warm water, followed by a thorough rinse and dry. For tough stains, a paste of baking soda and water is highly effective.

Why is drying stainless steel immediately so important?

Drying immediately prevents water and mineral deposits from forming water spots, streaks, and scale buildup. Critically, it prevents the prolonged exposure to moisture that can lead to corrosion and rust over time.

Can vinegar be used to clean stainless steel in a commercial kitchen?

It’s generally advised to avoid using pure vinegar for regular cleaning, especially in a commercial setting, as its acidity can potentially dull the finish or, with long-term exposure, damage the protective layer. If used for light degreasing, it must be a heavily diluted solution and rinsed off immediately.

How do you get rust off commercial stainless steel equipment?

To remove light rust, use a mild abrasive like baking soda paste or a non-chloride commercial stainless steel rust remover. Gently scrub with the grain using a soft cloth. Never use steel wool, which can make the problem worse by leaving carbon particles behind.

What is the “grain” of stainless steel, and why does it matter?

The “grain” refers to the faint, microscopic lines running along the surface, created during the manufacturing process (the grit finish). Cleaning with the grain prevents cleaner and dirt from getting trapped in the lines, which causes streaks and scratching, helping you achieve a superior, streak-free shine.

Conclusion

Cleaning stainless steel in a commercial kitchen is much more than just scrubbing. It’s a calculated process of following strict procedures: cleaning with the grain, using approved alkaline-based, chloride-free solutions, and always, always drying the surface completely.

By adhering to a firm, documented maintenance schedule, educating your staff, and investing in the right non-abrasive tools and chemicals, you ensure a sanitary environment, protect your expensive equipment from pitting and corrosion, and maintain the professional polish that reflects a high-quality operation. Keep it clean, keep it safe, and keep it gleaming.